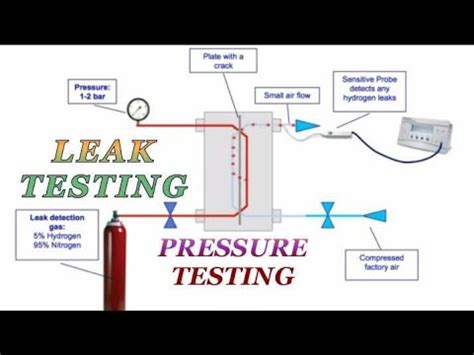

Negative pressure Leak Tester distribute|system pressure testing for leaks : Chinese This leak testing method capitalizes on the fact that a leak will allow a quantity of gas – remaining uniform through a period of time – to enter a sufficiently evacuated device (impeded gas flow, see Fig. 1.1). . the test gas which has . WEBКіліан Мбаппе Лоттен народився 20 грудня 1998 року у 19-му окрузі Парижа та виріс у Бонді, Сена-Сен-Дені, комуні, що знаходиться за 10,9 км (6,8 миль) від центру Парижа. Його батько, Вільфрід, родом з .

{plog:ftitle_list}

Super Sete - Desdobramentos e fechamentos da Lotofácil - L.

system pressure testing for leaks

multi chip package test

Duct Leakage Testing – RETURN SYSTEM. Per ANSI/ASHRAE Standard 90.1-2010, “positive pressure leakage testing is acceptable for negative pressure ductwork”. Even so, you will see specifications that may require return air or exhaust systems to be leak tested under a vacuum .Ductwork Leakage Testers. The TSI Positive and Negative Duct Accreditation (PANDA) System, PAN200 Series, is designed to provide fast, accurate duct leakage detection, as well as duct performance measurements.For negative pressure testing (5b), the fan intake will be connected. With McGill AirFlow’s 4-inch Leak Detective test components, the fan comes equipped with a tapered nozzle, which can .testing and the procedures to be adopted in carrying . Low pressure ductwork system suitable for a maximum positive operating pressure of 500 pascals and a maximum negative pressur e of -500 pascals. . • The level of leakage is related to the air pressure in the system and it is generally accepted that leakage will increase in proportion .

This leak testing method capitalizes on the fact that a leak will allow a quantity of gas – remaining uniform through a period of time – to enter a sufficiently evacuated device (impeded gas flow, see Fig. 1.1). . the test gas which has .

The presence of a trend component in the pressure signal has a detrimental effect on the accuracy of pipeline leak detection based on the negative pressure wave (NPW). To address this issue, a trend judgment criterion based on the signal interval statistical distribution (SISD) is introduced. In addition, an adaptive trend removal method is developed by .Vacuum and Pressure decay leak testing Venice, 22. March 2019 Presenter: Dr. Matthias Kahl, Head of R&D WILCO AG, CH . –LFC, P, V (different types) –pressure curve / course –steps of the differential pressure test • Method selection • Equipment in process control • Applications of differential pressure . most similar to negative . This article explores the negative pressure test in drilling, explaining its importance as a safety protocol and detailing the steps involved. . Any drop in pressure indicates a potential leak or defect in the system. Example: Let's say a storage tank is undergoing a negative pressure test with a specified test pressure level of -5 psi. If .Per ANSI/ASHRAE Standard 90.1-2010, “positive pressure leakage testing is acceptable for negative pressure ductwork”. Even so, you will see specifications that may require return air or exhaust systems to be leak tested under a vacuum (negative pressure). To perform a proper duct leakage test under negative pressure using an ORIFLOW duct leakage tester, perform .

Leak Testing 101: A Primer 4 Vacuum Decay Leak Testing Similar to pressure decay leak testing, vacuum decay leak testing evacuates air from the part or system under test to detect leaks. Vacuum decay leak testing is commonly used with parts that could have leaks from external sources, such as underwater sensors, pipes, or outdoor electrical .

The pressure increase leak test method can be a good alternative to trace gas methods, given the ability to test parts at very high pressures (up to 1,000 bar), with very short cycle times. . This measuring chamber is not directly pressurized with positive or negative pressure but is dosed via a previously evacuated or filled pre-volume. The .What is a Vacuum Decay Leak Test? Vacuum Decay leak testing is used on a variety of products that can only be leak tested at negative pressure. The Optima vT can be used to leak test products, typically less than one liter at a fairly low vacuum, < 0.25 atm. Testing products greater than one liter can be achieved with high flow valves.Air leak testing is a common method used for leak testing. It is a flexible test method that can be used to leak test a wide variety of parts and applications. Under the umbrella of air leak testing are several specific methods. In this ebook, we’ll cover the following types of air leak testing: > Pressure Change Method A

no duct leak testing

Understanding the negative pressure test on a drilling rig is crucial for maintaining control and ensuring safety. This article explains the importance of this test and provides a step-by-step procedure for conducting it effectively. . If the pressure drops, it may indicate a leak in the chamber or a malfunctioning component that needs .Pressure decay is one of the most widely used methods of leak testing in manufacturing and is ideal for a sealed component with an access port. In this test, a product is attached to a leak tester and filled with air. Once pressurized, the air source is valved off and the pressure is allowed to settle. Additional fit test series were accomplished with each mask type by inserting leak sources between each subject`s check and respirator faceseal. The leaks were used to achieve a distribution of fit test results above and below the test acceptance criterion of a fit factor of 100. Study results show that the controlled negative pressure system .Learn proper anesthesia machine operation, maintenance, and troubleshooting in this how-to video focused on performing a low-pressure system leak test.

Dry air leakage rate measured at 1 atm differential pressure across an orifice leak (i.e., leak inlet pressure of 1 atm versus outlet pressure of approximately 1 Torr) at 25 . The theoretical correlations of orifice sizes to air leakage rates were provided by Lenox Laser, Glen Arm, MD. Leakage rates are approximation ranges.

Causes of Negative Pressure. Negative pressure in pipe flow can arise from a variety of circumstances. Firstly, a sudden change in flow velocity can lead to negative pressure. This abrupt alteration could be due to the closing or .Negative pressure wave is a popular method to detect the occurrence and location of leak incidents in oil/gas pipeline. Three core technical challenges and related algorithm are discussed in this paper. The first is data quality. The balance between noise level and locating precision is discussed in filter design. The second one is dynamic slope in anomaly detection, whence a bi .

The positive and negative induced pressure tests described in the troubleshooting guide can be very helpful, as is following the procedure for flooding the hydro block by shorting the float switch position on the distribution board. Induced positive pressure holding test then walk away for a half hour. If that doesn't produce a leak, then valve . What is a Leak Test? Leak tests, on the other hand, are performed to detect and quantify leaks within a system. Rather than merely identifying weak points, leak tests aim to measure the leak rate or the amount of fluid that escapes from the system over a given period. The Concept of Pressure Decay. In leak testing, pressure decay is a commonly .AHU Case Leak and Pressure Testing: With the AHU test chamber prepared for blower pressure testing, slowly introduce air into the chamber using the rig blower fan speed controller on the test rig. Advance the fan speed until the desired test pressure is achieved. Holding the fan speed steady, measure and record the orifice differential pressure.The MPS 200 is a proven workhorse, operating on Pressure Decay for leak testing. The Electronic Pressure Regulation ensures accurate test pressure control, while the high accuracy flow sensor decreases test time and minimizes errors. The MFS 200 is available for both internal pressure test, as well as negative pressure vacuum tests.

test equipment – nitrogen enriched air distribution system negative pressure leak check 7 Aviapool (Aviation Tool Pooling LLC) is a global company providing around the clock assistance for the planning, supply, and sourcing of tooling equipment to . The negative pressure wave approach is definitely useful in pipelines carrying liquids, but the energy of the pressure wave is spent during long flow pumping in gas pipelines. The concept of a detection and localisation method based on pressure drop in a leak free pipeline (pressure gradient method) is linear as shown in Fig. 8.

Leak localization can be performed in transient state, using a model of the dynamic effects of the leak in the time series like negative pressure waves, or in steady-state, namely comparing the flow and pressure measurements inside the DMA against a reference that was acquired/generated/modeled in absence of leaks. Steady-state methods are the .NBC Leak Tester Mk II/Fitment tester is an automated field usage electronic tester which evaluates the fitment (leak tightness) of NBC respiratory full-face mask. This is a Controlled Negative Pressure (CNP) based quantitative fitment type instrument. Salient features: • Micro-controller based system with data storage facility • Consists of .Only the negative pressure leak test detected all 54 leaks, a significant difference from the positive pressure test, which detected the least number of leaks, 28 (P < 0.05). Some leak tests are more suitable for specific anesthesia machines. Adoption of the negative pressure test as a universal LPS leak test may prevent the risks associated .Leak Testing - TQC's beginners and fundamentals guide to helium leak testing, what is it, why use it and the benefits of helium leak testing. Please call: +44 (0)115 950 3561. . To reduce the effect of a large leaker one can; build up to the full test pressure in stages, build up to the full concentration, flush the mass spec with a gas with .

webOver 30 years of excellence in design, manufacture, installation and maintenance for chemical & liquid storage solutions.

Negative pressure Leak Tester distribute|system pressure testing for leaks